Darkroom

The Darkroom Project 2

August 2021

Back in December 2019 I was planning a new darkroom after we moved house. Well, COVID happened, and plans went into slow motion or effectively stopped. After some review of how we were going to use the house, we decided to adapt the smallest bedroom to a darkroom rather than frame a space in the spare garage bay. The bedroom is about 11’ by 10’ with a built-in closet, though the door clips one of the room corners. Call it 105 square feet, plus the closet and swept area of the doorway.

The Initial Plan (which never seems to last)

The current floor is fitted carpet, and that has to go. A quick check indicates that it is the usual gripper strips and underlay. How level the floor is will be seen when the carpet comes up.

The new floor will probably be Pergo (TM) or similar, which will offer decent water proofing, and will be a suitable floor if the room gets repurposed again. Blackout will be done using adhesive Velcro and blackout material over a frame initially as there are two small fixed windows and one large opening window. This approach was chosen so that the windows can be accessed for cleaning every so often.

Plumbing is possible - the guest bathroom sinks are on the other side of one of the walls - but is not planned for the moment. Past experience indicates that water use is not that high apart from washing, and with the guest bath and the laundry on the same floor there are options. Indeed, the Jobo has been running in the laundry during the darkroom hiatus! California is heading for water use restrictions, so I need to be conscious of what I use.

I am planning to set up at least two Beseler 45 enlargers. The older M45 will be used for smaller formats up to 4x5, while the newer MXT will do 4x5/6x12, and get the 8x10 conversion (which is another story). The MXT will be rigged over a drop table. With my 8x10 arrangement it is easier to drop the table than work with the head above the chassis cross-bar. Routine work will be at the usual standing bench height. I may bring the old Durst M605 back into operation for smaller formats and for doing print flashing. It all depends on the need for bench space.

The sink will be opposite the enlargers, and should leave about a 4’ space in the middle of the room. The sink unit is intended to be about 7’ in overall l ength and some 6’ wide for the actual sink. The under-sink space will hold trays and spent chemicals, and some of my drying racks. I may put a rack in over the sink as in the old darkroom to hold more - I will need to hang film there anyway.

Fume extraction is desirable, but that will be dependent on roof or window options.

The dry bench will be 15/32" finished plywood. This is a nice balance of strength and ease of cutting. Because of the drop table, one end will be 18" by 3’, and the rest 4'6" by 3’. The drop table will be accomodated by the gap between the end drawer unit and the next one in line. The main run of units will be two 2’ wide, and one 18", then the drop table gap, then the 18" unit in the corner. The main challenge will be getting the units/bench top level, and ensuring the supports for the drop table levels are parallel to the top. The units will all be drawers, as the closet area will be available for oversize items. I am considering a beverage cooler (2’ under-bench) as a film and paper store and a source of chilled water.

The room is part of the house HVAC system. How this will work in practice I am not sure. On the one hand it is a dust ingress, but it also provides some positive pressure when active and the door is closed. The room is on the ENE corner of the building, and gets morning to early afternoon sun, so it won’t be cold. Closing the HVAC vent is possible but this can affect the total air volume flow in the system. Fume extraction will have to consider the HVAC flow, as there is no point in extraction if it cannot handle the HVAC flow. It is not desirable to pump any fumes through the house.

Here is the basic room before conversion, scanning right to left from the door.

More thoughts on doing a drop table

The Beseler base is some 25 inches wide. The drop table needs to be wider to allow the 20x16 Saunders easel to be shifted a little. So it is probably going to need around 36 inches overall. This means the bench top will have an overhang on each side that will need support. Getting the shelf support level, especially if the new floor settles with time, means some form of adjustment.

My initial thought for adjustment is to use cabinet leveling feet upside down on the support battens. This will give a four point adjustment and support.

Temporary darkroom

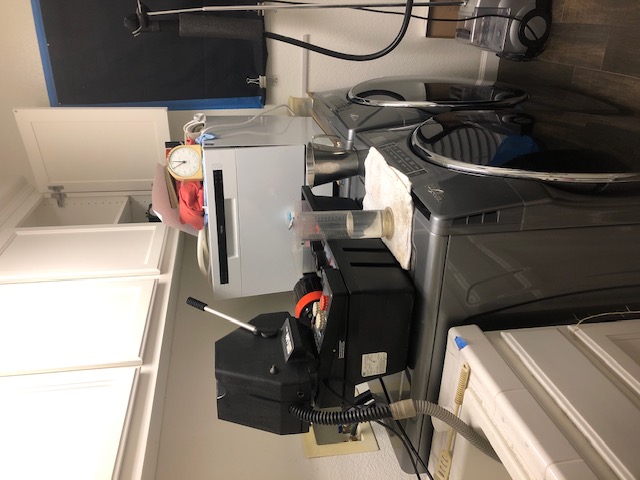

I have been using the laundry room as a temporary darkroom for a while, since the conversion plans were put on hold. This is not especially convenient - we do laundry three times a week. I need to vacuum the space before setting up and wipe down surfaces to pick up fabric lint. For the Jobo processor all that is needed is to move it from storage to the top of the washer, fill the tempering tank, and turn it on. I have power close enough, and the sink for drainage. Film loading can be done in the room, or using a changing bag elsewhere. Having more space makes working with film holders easier.

Space is tight for printing. If I fold down the wire shelf on the wall I can just get a cart with the Besler MXT into the room. If I only need 6x6 or smaller, then the Durst M605 is enough. Printing space is limited to 8x10 sheets.

I have put a temporary blackout on the window, and I have a blackout curtain outside the door. The house has good internal light, so the curtain is needed during the day. Using the curtain avoids sealing the door, so there is air flow for the extraction fan.

There is a safelight mounted midway along the empty wall pointing at the ceiling which gives a good overall light for printing.